|

|

The History of This Website Glassblowing Here I am in the Glassroots hotshop, working on a bottle shape, preparing to transfer

to a punty.

I have done this now for about 5

years and finally, mainly under the guidance of Jason and my continued

collaboration with Charlie, who is a daring experimenter, start to get

somewhat of a grip on some of the techniques. The reason to write about it is not

because I have reached expertise. Not by a mile. But I am obsessed with

ringed blown glass and after many, many failures it seems I am making some

progress. I will keep this as a record of what I try, what seems to work and

what fails and why. Two of my favorite object shapes are

bowls and bottles, which both have their idiosyncrasies in the creation

process. Early in my glassblowing efforts I came across the two excellent

videos by Powell Scott in making ringed bowls. Here is a blown bottle on the pipe,

ready for transfer. I had to do many, many trials before finally mastering

this seemingly simple but beautiful shape. No Good Glass Ring Molds Creating colored rings in a blown

glass object can be done in at least two ways: You apply the colored rings on

a bubble or parison or the rings are already part of the set-up. Applying

colored rings by rotating colored glass off from a punty on a parison on a

pipe is certainly possible, but extremely difficult to get an “incalmo” effect. I have tried it several times and found

the technique interesting but difficult with not the desired effect. Creating an “embedded” rings piece

requires, well, glass rings. Preferably all of the same diameter and

different colors. When stacked in a cylinder, and having all rings tack-fused

to each other, you have the basic set-up for a blown ringed piece. This is the, for me, stunning thing.

While we have a technical solution for almost anything, there are literally

NO MOLDS to fuse frit (or ground glass) into a ring. Especially for rings

that are required for the ringed bowl, which would be a ring of about 2 -2.5

inch outside diameter and an inside opening of about 1.5-2 inch leaving a

ring with a thickness of about ¼ inch. The only somewhat useful mold I

found was a Colour de Verre re-usable

mold for napkin rings. While the created rings are beautiful, they

are too large and too thin for making the required cylinders. I tried it and

below is a picture of the molds before fusing. I also made a circle, with the

intent to drill the inside opening out with a diamond hole drill. I found the

risk of breaking the glass and the work involved too much, and for now I have

not pursued that technique. It really comes down to making your

own rings, or making your own molds. I have considered many options and

worked on some that work. Two options that I probably will try is 1) using a stainless steel muffin tray, burn in the tray in an oven,

then lightly sandpaper it and coat it several times with kiln wash for

release. I will use a center piece of pipe covered with fiber paper to create

the opening and fill the created ring with glass frit. A second option is to use a stainless steel donut tray. The size of the donuts fit

with the requirements of the size of the rings. Both the muffin and donut

tray have a slightly conic shape, facilitating the release of material from

the mold. I believe I can sufficiently shape any stack of rings with the

jacks to create a cylinder. Unfortunately, the problem with the donut tray is

the nonstick coating that all of them have and which has to be removed. This

is yet another issue to be addressed and I have placed in on the back burner.

Ringed Bowls The technique was invented by Boyd Sugiki, I believe. Boyd turns out to be Jason Minami’s

teacher, which explains a lot of how both seem to “know” and “understand” hot

glass. Boyd and Jason (as well as Hannah) are these ultra-patient instructors

who never seem to get upset with a student. Not only do they understand glass,

they understand people also. Anyway, the technique of Boyd is as follows. He

blows 2 or more colored cylinders of equal diameter. After cooling, he cuts

rings from the cylinders with a diamond saw, re-stacks the rings into a

cylinder again, but now with different colored rings. He stacks the colored

rings as a cylinder in a kiln, heats up the stack until the rings are fused

together. Then he picks up the rings from the kiln on a blow pipe and heats

the stack of rings in the glory whole and blows and shapes it into a piece.

You can see the amazing result on Boyd’s website. For instance his blown sculpture of light and dark blue rings

takes your breath away. How do I know Boyd? He gave a course

in making bowls at Glassroots. The details of this course can be seen online

in a video posted at the Corning

Studio website. Powell Scott took the effort to

video record his efforts to create the rings which he calls the set-up, and then

blow the ringed bowl a

nine-ringed bowl no-less. It gives an impression, but not really the

skill and effort required, how to get to the final result. Different Ring Techniques I contacted Powell which some

questions about making the rings, and he very graciously responded. My

initial reaction was (what the heck did I know about glassblowing?) if there

were no other ways to make the rings. Powell was not aware of any

alternatives. I had considered 3 alternatives, without of course knowing the

obstacles that these would experience. 1) use glass frit (basically ground

glass) in a ring mold and fuse it in a kiln, This

creates opportunities to have different colors and patterns of colors in a

ring. 2) use a glass rod, drill a hole in it, stack the rings with holes in a

kiln and pick it up, and 3) use glass sheet and cut or drill rings from

these. The last options would allow you to have very thin colored rings. I

have modified this technique to an easier path. That is, use clear glass

rings cut from a cylinder and add a thin ring cut from sheet between them. Or

in the alternative have clear (or colored) cylinder blown rings and add a

thin layer of frit glass fused to it in a kiln, I explain later why. Here are two stacks of cut slices of

a color rod with holes drilled. Anyway, Powell was intrigued about

the glass sheet rings. And while I was still struggling cutting rings from

sheet glass, he designed a contraption to make the glass drilling easier and

he actually created a tumbler from these rings. It was an amazing piece of

work and you can see it at Powell’s Instagram Account.

Here are his pictures of that effort.

I can take credit for the idea, but

the reduction to practice (as it is known in patent vernacular) is clearly

Powell Scott’s achievement. It also hit me that my glassblowing

technique was not advanced enough to actually try to create a ringed object

as I was completely unable to control shape, thickness and keeping rings

parallel. So, I gave up the ringed technique and had additional training in

glassblowing technique by Boyd Sugiki, Nadine Saylor and Jason

Minami. Instruction videos by Nikolaj

Christensen were also helpful. State of Technique The following picture gives an

impression of the state of my skills later in 2022.

Ringed Bowls Again I still had a set of cut rings and I

wanted to move on from bottles to something else for a while. So, Charlie and

I tried a novel approach. The Glassroot hotshop has a shovel-like implement on which I could put

4 rings next to each other and heat it in the garage. After sufficient

heating Charlie would stack the rings on a piece of maple wood and I would

blow a bubble into it. The rings would sometimes not be hot enough or cooled

to fast and would break when blowing a bubble in it and drop off from the

bubble. A solution was to create a wooden

mold that would hold and align the rings and allowed the bubble to be forced

against the inside of the rings. Sometimes the rings would break, but overall this worked. The following show a picture of clear

glass rings holding a colored ring. After careful heating and blowing with an

extra gather and using Boyd’s bowl technique I would first get the following

result.

You can see improving results of

creating a parallel structure during blowing from left to right. The better

structure was created by more aggressive paddling of the bottom right from

the start on the pipe. In order to better hold the rings or

rather force the rings on the bubble, I used a self-made wooden mold like

shown below. It can open and close, so the rings are forced into a cylinder

shape when I blow a bubble into it.

This method does work and with practice

I got better and better bowls. However, with the blown bubble it was not

really possible to work the inside and outside of the bubble on the pipe as

the bottom was closed off, of course. In the Kiln I decided to give it a more serious

approach and arranged lessons with Jason Minami to get instructed on kiln

picked-up cylinders. Jason’s very first exercise was for me to create a more

stable platform for the stack to be fitted on the pick-up pipe. For the

pick-up platform you take a first gather from the furnace, hold up the pipe

to let the glass flow back on the pipe. Then place the pipe in the glory hole

and blow until an opening is created in the glass. Further open the opening

at the bench and then hold the jacks vertical and push the glass back on the

pipe. Then shape the glass on the pipe with the jacks or on the marver into a cone shape. The pipe opening now sticks

out. By cooling the so formed cone and later heating only the top of the cone

you have a more-or-less stable relatively cool platform for the pick-up. Go

to the kiln and pick-up the stack. This set-up makes a tremendous

difference as the cylinder does not flop around on the pipe after pickup. I

then carefully heated the cylinder and worked its inside and outside, shaping

the end into a parison, eventually closing the cylinder off. Later I would

close the cylinder off with a cookie dropped from a punty on the marver as not to lose colored glass to the bottom. There

are several other tricks I learned from Jason in this. All good. The most

counter-intuitive trick was not to push the glass off the pipe from the moil

after gathering. Many glassblowers do that in order to create a thin neck.

Jason’s technique is to keep the moil glowing hot. He calls it your “money in

the bank.” That keeps the glass fluid at the moil, while you cool the bottom

and then blow. The hot glass at the moil or neck will expand during blowing

and pulls the glass off the moil. With sufficient glass thickness everything

stays stable. In contrast when you strip glass from the moil all the glass is

at the bottom. Even when you don’t heat deep, the neck becomes more or less

fluid and makes the piece a flopping creation, causing a struggle to keep

everything stable. Anyway, these are some of the

results using Jason’s lessons.

And here is another one:

I gave the “shovel” based approach

another shot, but now creating a stable cone on the pipe as taught by Jason

before I blew a bubble into the stack. This requires some careful work with

the jack as you want to create a stable pick-up platform with a bubble

sticking out. The way I did that is by creating a bubble from the first gather,

then creating a neckline near the edge of the pipe and pushing the glass

back, and shaping the remaining bubble into a cylinder that fits into the

pick-up. This requires a bit of exercise, but it works well. Below is an

example of the result. New Rings All the above were made from rings

cut from previously blown cylinders, then cut, etc. I still want to use frit

made rings. So, I ordered stainless steel rings from Speedy Metals, a small diameter

internal ring and a larger size external ring, to fill up the space with frit

and fuse it in the kiln. I did the filling at the Glass Underground Studios

in Warren, NJ, where the staff is extremely friendly and helpful with my

projects. They helped me with selecting the right covering of the rings with

fiber paper for easy release after fusing and with creating the firing

schedule for the kiln. Here are the rings in “uncovered”

state. And here on a firing board with

rings covered and filled with red and yellow frit. I make marks on the thin

fire paper to align and center the steel rings. And this is the result after firing

and grinding. The white stuff is the residue of the fiber paper that washes

off under water and brushing it with an old soft toothbrush. And this is the result of the red/yellow stack blown

into a bowl I am told the result is very “artistic”.

And I agree. But from a technical point of view it

is a failure. Jason had already warned me that the frit rings are pure colors

and have the melting property of these “soft” or “hard” colors and bleed

through during blowing and are very difficult to control. The blown and cut rings have a

strong base of clear glass and have a more similar blowing behavior, making

blowing and keeping parallel rings easier. Back to the Drawing Board There are several variations that

work or may work. The first one is to use frit rings between blown rings.

While perhaps not ideal, it seems that the blown/cut rings will stabilize the

structure, as compared to using only blown rings. Well, that worked very

well. The following picture is of a bowl made from a combination of blown

rings and frit rings. The result was beyond expectations, with rings

maintaining the parallel structure. You can see one frit ring which was made

from yellow and red frit. One side effect is that the frit

ring on the inside is raw fused frit and uncovered by clear glass, as a

result of the approach taken. You can feel it, as it has a slightly rougher

texture than the blown rings. Part of My Ring Set The picture below shows a set of

rings I already made. Some are blown/cut, others are frit made. Also included

is the remainder of a red cylinder, which I can cut further if needed and a

clear glass cylinder, ready to be cut.

More Rings One approach taken, was to make

clear rings from a clear glass cylinder. Place the rings of a firing board,

wrap it with slightly higher fiber paper and hold it in place with pins. And

then put a thin layer of frit on each clear ring. Then fire the covered rings

in a kiln. Below you have the stack of rings

created that way. Unfortunately the fiber paper dam

is not very tight and colored glass was bleeding down.

But basically, you have clear rings

with a thin cover and some bleeding. And below this you can see the final

result in the shape of a bowl. The bleeding through is extensive. I call it

the Bleeding Heart Bowl. But technically it works

very well to have thin colored rings in a clear glass object.

In fact, the shadows demonstrate the very thin

rings that have been formed as an inherent part of the glass. Here is a second bowl created in a

similar manner. The bleed-through is more controlled leading to a thin ring

in a clear glass set-up.

The following image shows a stack of

rings. Rather than clear thin rings I use clear blown rings to create a

stack.

Such a stack is shown next:

The rings will be ground to remove

any burs. The bowl created from this set-up is shown in the following image.

The color rings are thus a type of insert. The creation of these sheet glass

rings is a pain in the neck, and a bit dangerous, as the drill sometimes

catches on the piece and rotates it, so it become like a very sharp rotating

knife. I always have cut-resistant gloves on when I work with this set-up. So, I the set-up was successful.

Jason Minami heated a stack of 1 inch high blown/cut clear rings, with

inserted sets of 2 sheet glass cut rings in a kiln to about 1250 F. I picked

up the tack fused rings on a blow pipe and created the following high bowl.

That worked extremely well. It also

shows that the intervening rings do not have to be sheet rings. The inside

open diameter of the color rings was smaller than of the blown rings, which

contributed to the expansion of the ring height. The diameter of the bowl is

about 30 cm. Next Round As every glassblower probably knows:

there are at least two aspects of glassblowing: 1) the technique/skills and

2) the artistic execution. Next I want to expand some

of the technique but also use more colors and designs. These cylinders are made from color

overlays, with contrasting sheet glass shards and blown out. Next they were cut into rings. My assumption is that during tack

fusing the sheet glass expands slightly. Based on that I have cut remnants of

sheet glass into tiny pieces and tack them to the upper surface of the cut

rings by using Bullseye glass glue (glasstac).

Presumably the glue burns off in the kiln. The rings are ready to go as a stack

into the kiln. I am already preparing other rings with combinations of

different color sheet glass. And then Jason Minami leaves Glassroots. This is

a setback, as my personal skills are somewhat shaky still. So, I need to

prepare for the next steps. Charlie’s assisting was critical in ultimate

shaping by cooling the punty and keeping bowl shape by paddling back and

front. Critical aspect in shaping the bowl is first opening the shape on the

punty with the parchoffis and then “breaking in” the edge with paper, so the

rim does not flare wide. Ron Johnson is now Glassroots’

senior glassblowing artist and he also is a gifted glassblower. I am happy to

say I took a lesson with him and I will continue with the “ring project.” After March 2024 So, Jason has left Glassroots and

Ron Johnson is for now lead glassblower. My benchmate,

Charlie Willis, had a relapse of his sciatica and had back surgery, which

puts him out of glassblowing until September. In order to keep working with

hot glass I now take lessons with Ron. The left bowl was made under Ron’s

guidance in the picture below, using ‘rings with shards’ a technique that

works well and I will continue with later.

Back to using steel rings as molds The results were OK, but one of the

drawbacks of the steel ring set-up, is the time it takes to complete even a

small set of rings. I was looking for more of a production-type set-up that

quickly creates 20-30 rings in one batch. (I am an engineer, after all). Anyway, I made the following bowl

from the above rings with Jeremy Unterman, the new hotshop lead at Glassroots and we had great fun doing it. After I expressed my concerns about

using steel rings as molds, Meryl Raiffe of the

Glass Underground suggested I give it a shot with Silkemat

a refractory fiber sheet that is wetted with a Rigidizer

and can be applied as a re-usable mold. I was a bit concerned about its

thickness and (in)-ability to follow/hold the form of a 2

inch ring. I tried several ways to get a nice repeatable shape of a

ring. For instance, I used the bottom of a donut pan as a negative mold. Here

is a picture of my ‘molding’ effort.

The results were not satisfactory.

Then Marthe, who is an accomplished knitter and crafts person, suggested I

use a round wooden stick she has for knitting purposes, to push a proper hole

in the wetted Silkemat. Rather than using the

entire mat, which bunches up, I cut squares, placed them over a large steel

ring with a wooden (curtain) ring in it and push the stick to form a ring

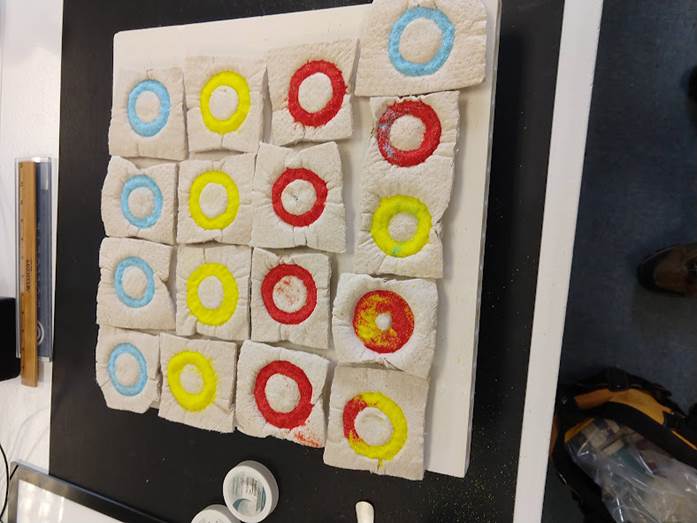

dimple with the steel ring preventing expansion. See the picture below for

the result. And below the final result after

being dried at 200F in the oven. This work fairly well, with quick

filling with powder frit, the following set came out of the kiln. There are

some burs on it, but these are easy to sand down. I also bought Modeling Glass binder

to make a glass frit paste. First, I had to make a ring cutter to cut 2.5 inch rings out of the paste. Then I made the paste

from 00 frit and below you see a result. The ring cutter is made from plastic

biscuit cutters in a set and I glued two concentric biscuit cutters on piece

of plastic. This made production of the rings

extremely easy. And I made a batch of a couple of dozens of them. Here is a

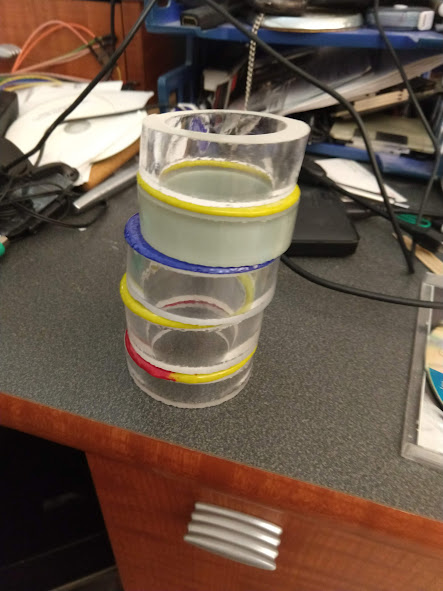

result in the kiln before firing. Here they are after firing.

The size and thickness are

excellent. Only the yellow is dull. I exchanged some e-mails with Lois Manno,

the developer of modeling glass. She suggested that firing in the gloryhole

of the glass may strike the yellow and they may come out bright. I made a stack of thick rings and

combined with Modeling Glass rings (see below) and I will post the result

after I try to make a bowl out of that stack at Glassroots. So certainly, Modeling Glass is an

easy, convenient and reliable way to create glass rings on a production

scale. Yet, another way that I considered

but had not yet executed, is commissioning Glass Underground’s Doug to

program their CNC-watercutter Wazer to cut

rings from sheet glass. I had 3 sheets of 3mm COE 96 glass and Doug did a great

job of cutting 2 times 8 rings from each sheet.

Rings, Rings, Rings I have now an abundance of rings of different

quality and diameter. This forces me to create matching sets of cylinders at

Glassroots, which I am working at. Glassroots will upgrade its glass furnace

in July and close for the rest of the summer. So, I will have to work on

making (and cutting) cylinders in the near future. Jeremy suggested using a

blow-pull approach to quickly create a cylinder. So, I will try that. Corning Course The good news is that my application

at Corning for a week’s course conducted by Boyd Sugiki

was accepted. Boyd is the inventor, I believe, of the cut-cylinder rings

method, or faux-encalmo method, and I am looking

forward to being instructed by the Master so to speak. Fortitude So what, if

one has run out on XOR and AND functions? The next

reasonable step is to create the XOR and AND

function from adequate connectives, such as NANDs. What if there are no NAND

functions? It turns out that at that stage, one is not able to create the

simplest of simple ripple adders, which is the addition of two bits. It reasonable to assume that an addition of two words of two

bits with a ripple adder is more complex than an addition of two bits. The

reason for that is that additional layers of interconnected logic have to be

provided. |